The industrial web of points (IIoT) is using smart sensors as well as actuators to enhance manufacturing as well as industrial processes. Also known as the commercial web or Industry 4.0, IIoT leverages the power of smart makers as well as real-time analytics to make the most of the data that dumb makers have created in commercial setups for years. The driving ideology behind IIoT is that wise machines are not only far better than people at capturing and also examining information in real time, they are better at interacting vital details that can be made use of to drive company decisions faster and also a lot more accurately.

Attached sensors as well as actuators enable business to detect ineffectiveness and troubles quicker, and save money and time along with supporting service intelligence (BI) efforts. In making particularly, IIoT holds great prospective for quality assurance, sustainable and also eco-friendly practices, supply chain traceability and also general supply chain performance. In an industrial setting, IIoT is vital to procedures such as predictive upkeep (PdM), boosted area service, energy management as well as asset monitoring.

Exactly how IIoT works

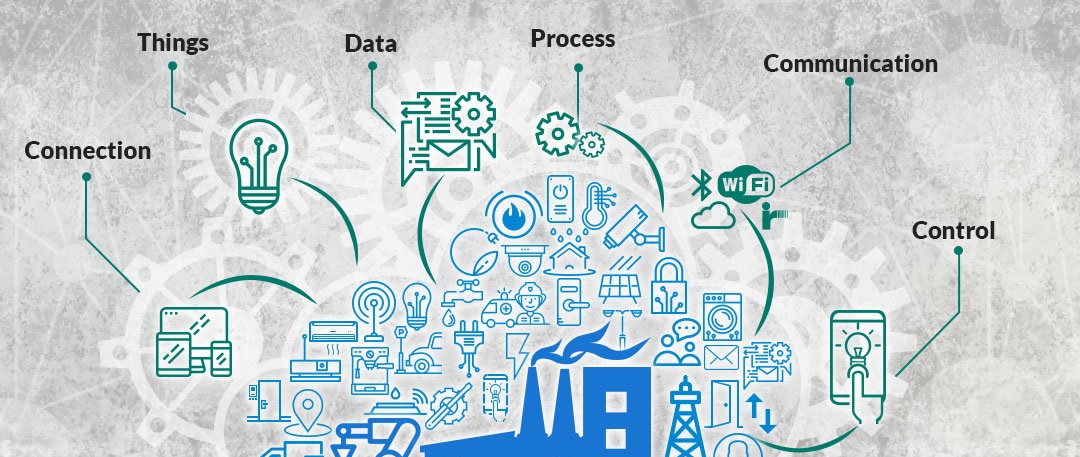

IIoT is a network of intelligent tools linked to develop systems that monitor, accumulate, exchange as well as examine data. Each commercial IoT ecosystem contains:

- Smart assets that can pick up, connect and store details concerning themselves;

- Public and/or exclusive information interactions infrastructure

- Analytics and applications that create service info from raw information; as well as

Edge devices and also smart assets send information straight to the information communications framework, where it is exchanged actionable info on just how a particular piece of machinery is running, for instance. This details can then be made use of for predictive maintenance, as well as to maximize company processes.

Advantages of IIoT

One of the leading proclaimed benefits the industrial net of things pays for services is predictive maintenance. This involves companies using real-time information created from IIoT systems to forecast flaws in machinery, as an example, before they occur, allowing business to do something about it to address those problems prior to a component stops working or a machine drops.

Another typical benefit is enhanced area service. IIoT modern technologies help area solution professionals determine potential issues in client tools prior to they end up being major concerns, enabling techs to fix the issues prior to they hassle consumers.

Property tracking is another IIoT perk. Suppliers, manufacturers and consumers can use possession administration systems to track the area, status and condition of items throughout the supply chain. The system will send instant signals to stakeholders if the goods are damaged or at risk of being damaged, giving them the opportunity to take immediate or precautionary action to treat the situation.

IIoT likewise allows boosted client contentment. When products are connected to the internet of things, the supplier can capture and also examine data concerning how customers utilize their products, allowing makers as well as product designers to customize future IoT tools and construct even more customer-centric item roadmaps.

IIoT likewise enhances center management. As producing tools is prone to deterioration, along with certain problems within a manufacturing facility, sensing units can keep an eye on resonances, temperature level and other aspects that could result in running problems that are less than optimal.

IIoT versus IoT

Although the internet of points and also the industrial web of things have numerous modern technologies alike, including cloud systems, sensing units, connectivity, machine-to-machine communications and also information analytics, they are utilized for different objectives.

IoT applications link gadgets across multiple verticals, consisting of farming, medical care, business, consumer as well as energies, along with federal government and also cities. IoT tools include smart appliances, fitness bands and other applications that typically don’t develop emergency situation scenarios if something goes amiss.

IIoT applications, on the other hand, link machines as well as devices in such sectors as oil as well as gas, energies and also manufacturing. System failings and also downtime in IIoT deployments can result in risky scenarios or perhaps dangerous scenarios. IIoT applications are additionally more concerned with improving effectiveness as well as enhancing health and wellness or security, versus the user-centric nature of IoT applications.

IIoT applications and instances

In a real-world IIoT deployment of smart robotics, ABB, a power and robotics firm, is using linked sensing units to monitor the upkeep demands of its robots to prompt repair work prior to parts break.

Furthermore, commercial jetliner maker Airbus has launched what it calls “factory of the future,” an electronic production campaign to streamline procedures and also boost manufacturing. Airbus has actually incorporated sensing units into devices and also tools on the shop floor and also outfitted employees with wearable tech, e.g., industrial clever glasses, focused on cutting down on errors and also enhancing work environment safety.

IIoT applications

An additional robotics supplier, Fanuc, is using sensors within its robotics, in addition to cloud-based data analytics, to anticipate the impending failure of components in its robots. Doing so allows the plant supervisor to set up upkeep at convenient times, lowering expenses as well as avoiding potential downtime.

Magna Steyr, an Austrian automotive producer, is taking advantage of IIoT to track its properties, including devices and car parts, in addition to instantly get more stock when essential. The company is also examining “clever product packaging” that is enhanced with Bluetooth to track elements in its storehouses.

Suppliers in IIoT

There are a number of suppliers with IIoT platforms, consisting of:

- Capability by ABB, a power and robotics business;

- IoT System by Cisco, a networking firm;

- Area by Fanuc, a vendor of commercial automation devices;

- Predix by GE Digital, a power administration business;

- Connected Performance Services by Honeywell, a software-industrial company;

- Connyun by Kuka, a supplier of commercial robotics (produced in collaboration with Infosys, an IT getting in touch with company);.

- Wonderware by Schneider Electric, a power management company; and.

- MindSphere by Siemens, an industrial production business.

The future of IIoT.

Bain & Business predicted commercial IoT applications will generate greater than $300 billion by 2020, double that of the customer IoT sector ($ 150 billion).

Similarly, IDC Research reported the top three industries buying IIoT in 2018 are making ($ 189 billion), with a focus on possession monitoring; transport ($ 85 billion), with a concentrate on products surveillance and fleet monitoring; and energies ($ 73 billion), with a concentrate on clever grids, while customer IoT investing will certainly reach $62 billion.

More optimistically, Accenture expects IIoT to include $14.2 trillion to the economy in the very same amount of time, growing at a 7.3% compound annual growth rate (CAGR) through 2020.