Penetrant inspection is a nondestructive method of detecting defects that occur in a non-porous material such as ceramic or metal. This is done by applying two substances on the surface, a penetrant and a developer. The penetrant shows the cracks on the surface, while the developer drains out the dye that is leaking from the cracks.

The liquid penetrant inspection system is one of the more common nondestructive testing techniques, which is affordable. The two types of materials used in dye inspection are fluorescent or visible penetrants.

Fluorescent dyes are sensitive since they glow when exposed to ultraviolet rays, hence they can easily be observed by the naked eye. Visible penetrants, on the other hand, have a red dye, which is loud.

When the white developer is applied to the surface of the materials, the red dye is visible with the white background.

The 5 Steps in Penetrant System Inspections

- Surface Cleaning

The surface is cleaned to clear it of dirt, oil, grease and any other contaminants that may prevent the entry of the penetrant into the defect. Where mechanical operations are used for this cleaning, etching will be required as further treatment, as metal may be smeared over the openings to the defects.

- Applying the Penetrant and Removal of the Excess

The penetrant is the applying through brushing, spraying, immersion in a dye bath or using a dye penetrant system. Soaking time of between 5 to 60 minutes is allowed. This period is dependent on the size of the defect that is sought; narrower cracks require longer soaking time. The dye should, however, not be allowed to dry. Excess penetrant is then removed from the surface, but this is done carefully so as not to displace dye inside the crack. Removal is done by the use of a solvent or by rinsing in water/emulsifier.

- Applying the Developer

A white developer is then applied to draw the penetrant from the defect where it is lodged to the surface where it will be seen. These come in forms such that can be dry-dusted, sprayed or by dipping, the choice of which is determined by compatibility of the penetrant with the developer. It then stays on the surface for as long as it is needed to extract the penetrant; usually 10 minutes, but can be longer where the defect is narrow.

You can test the porous and non-porous material using Rebound Resilience Tester, it is the best way to check for feasibility of material used.

- Inspection

The flaws are then inspected under ultraviolet or natural lighting, and conclusions drawn from the characteristics observed.

- Cleaning the Surface

After inspection and recording of the defects are completed, the surface is again cleaned to clear it of the developer.

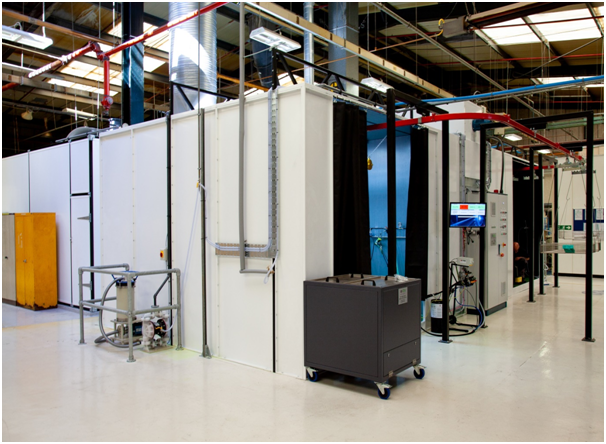

A penetrant system inspection is done to ensure that materials are not defective, and this should be done using bespoke NDT equipment. The liquid penetrants that can be used are either the fluorescent or the visible ones. A developer is then applied afterward to pull the dye up through the crack. If you are looking for penetrant systems for sale, purchase trusted brands.