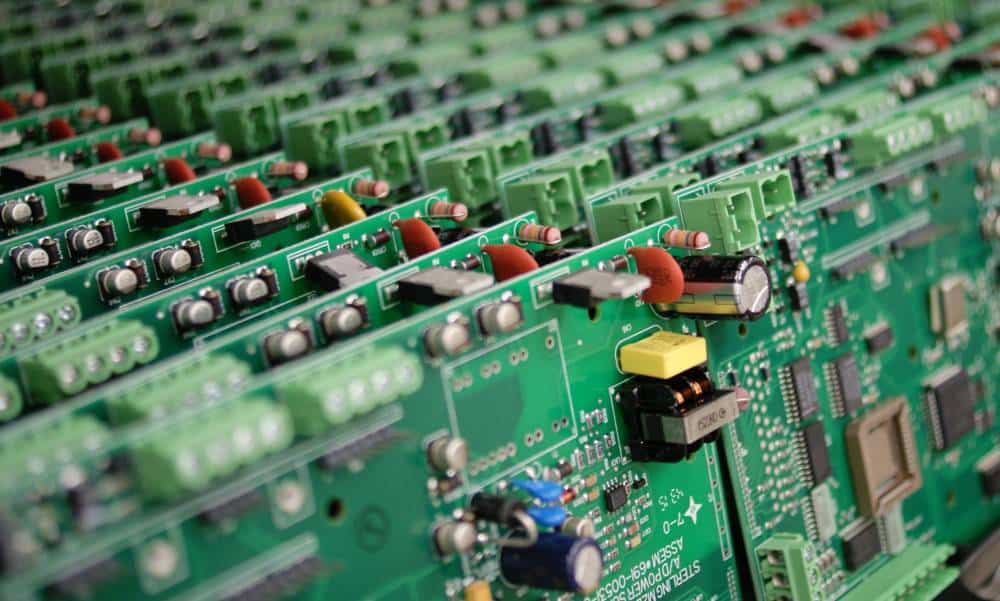

Nearly all electrical engineering products use printed circuit boards, also referred to as PCBs. These boards are in charge of supplying electricity to all commercially sold electronic devices. Printed circuit boards (PCBs), for those who are not familiar, are the foundation upon which various parts and electrical components of a device are connected to one another. In addition to the most fundamental one, which is providing power to the relevant device, PCBs are also in charge of a variety of other duties.

These duties include applying the right tuning mechanisms to the equipment to ensure effective operation. The printed circuit boards (PCBs) used in each device are unique and can be customised because the majority of devices are unique and depend on a diverse collection of parts and mechanics. The main purpose of a prototype PCB is to enable mass production of the same device. An overview of the procedure for producing a PCB prototype will be given in this article.

How does it operate?

Many PCB manufacturers can be found online if you do a search. These companies work with electronic producers, enterprises, and even designers to produce printed circuit boards for a range of goods. The design process is a time-consuming one made up of multiple smaller activities. Despite the fact that many clients already have their prepared PCBs, which are used in later manufacturing, getting a fresh prototype PCB takes time and effort.

The product’s specs, which will serve as the basis for further design iterations, will be thoroughly understood by the manufacturer’s design team. The prototype printed circuit board (PCB) will be put through its paces at each stage before the final product is approved; in most situations, the procedure will be repeated more than once. The procedures remain essentially the same, even though the design strategies have changed significantly in recent years from what is described here.

- Creating the printed circuit board’s schematic

- Designing the board’s layout

- Production, which includes fabrication and printing.

Choosing a Firm

Choosing a company with extensive experience across a range of industries is crucial for you to do before making your choice if you require PCB prototype assistance. The company’s history should be familiar to you, and as a new client, you have the chance to ask for references and discuss some of their previous projects. Make it a point to inquire about their normal clients, and don’t be hesitant to ask how prototypes are made.

You must also be certain that the concerned company will make the necessary efforts to test the China PCB before proceeding with the actual manufacture of the goods. It goes without saying that you should think about how much the finished China PCB will cost. Depending on the type of services they offer and what the customer wants, companies that make printed circuit boards may also do research and development work on prototype PCBs.

Choosing the correct company makes buying prototype PCBs affordable. If you are delaying production, the operation must be fast. To further compare prices, obtain an estimate. Before hiring a provider, call their customer support staff to discuss project issues, requirements, and expectations. Estimates let you compare prices. The final PCB prototype ends the first phase of production.