Manufacturers always use lightweight curing materials to make omnicure UV curing systems. This is due to their bonding efficiency. With numerous adhesives and a lot of machines in the market, you need to know how to operate the units.

Since its inception many decades ago, UV curing technology has been applied in various applications. At first, with adhesives and coatings, and developing into abilities like form-in-place gaskets, temporary potting, and masking compounds. In a situation of bonding, every adhesive features its own strengths and limitations. So, it might not be clear which item is fit for the project at hand. Selection is based on the adhesive’s properties, balanced with the process demand and requirements of the applications.

Once you know how the UV curing process works and the technology used, you will be able to make better choices and optimize the process. Therefore, what can you do to achieve the best results?

Narrow Vs. Broad Spectrum Lamps in Curing

There are two kinds of lamps: the LED-based UV curing and broad-spectrum mercury arc UV lamps. The LED-based UV lamps tend to have narrow spectral output. The conventional broad-spectrum lamp is the workhorse in this field. However, it has some disadvantages that you might need to compensate for. This includes the lifespan of the bulb and the intensity that reduces with time. On the other hand, LED UV curing lamps have a consistent output, no bulbs to substitute, and they don’t have any warm-up time.

For impressive results, bear in mind that the adhesive should match with the output of the curing lamp. Also, not every adhesive will cure optimally with narrow-spectrum light from an LED lamp, needing a wider range of light energy to attain the tack-free and great cured properties. It would help if you matched the spectral output of the omnicure lamp to the light responsiveness of the adhesive. This is an important step in doing the process right.

What is a Curing Dose?

The benefit of UV is that a complete cure is attained in a bondline within seconds. For this to happen, it’s vital to ensure the adhesive gets the proper dose of UV light. The majority of curing adhesives commence curing the moment they are subjected to proper light and will stop once the light is removed. For this reason, it’s essential to make sure a complete cure is attained in the exposure procedure.

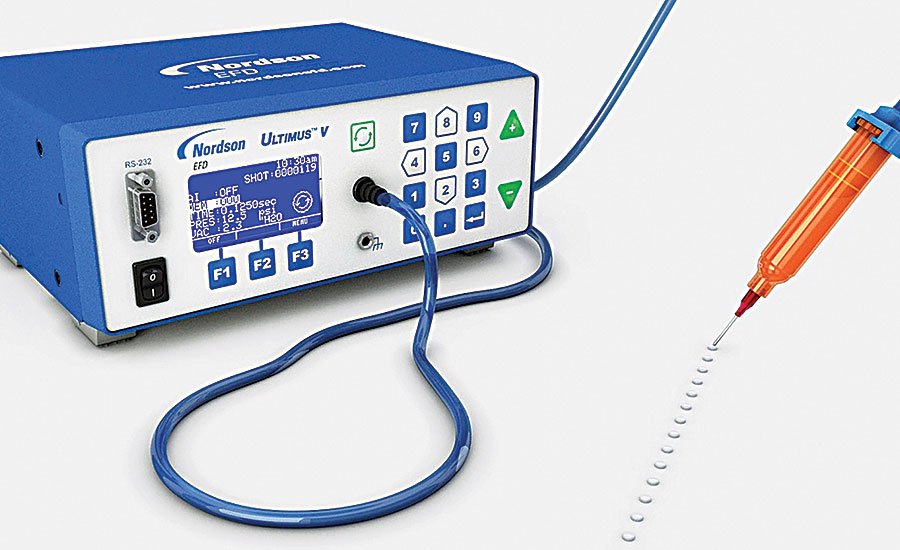

You need to test your procedure to define the least light dose to attain an optimal cure for your application. A curing dose is a mixture of light or power intensity and the duration of exposure. High-intensity lights lead to a faster cure and process effcentivess. More energy will offer you a good cure enhancing performance.