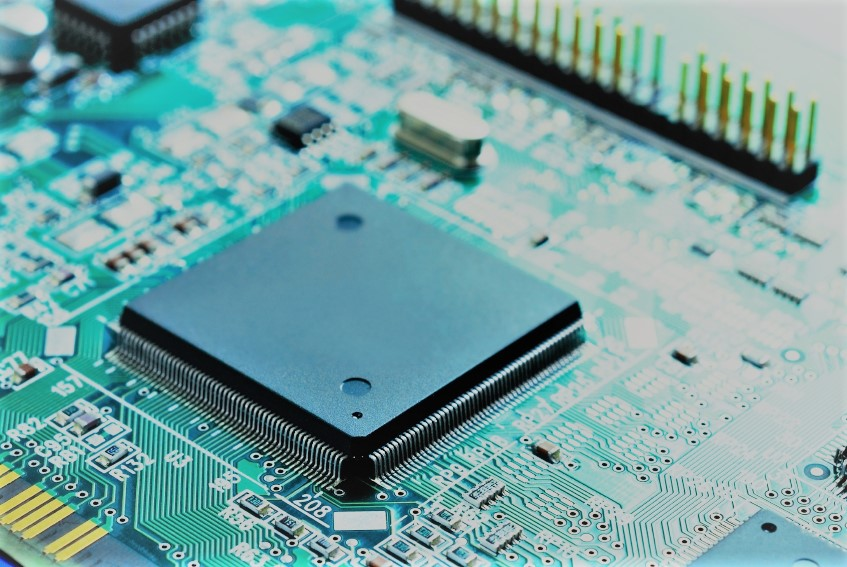

Integrated circuits are small electronic circuits that are designed to perform various functions. They act as amplifiers, timers, oscillators, computer memory, and even microprocessors. They are made by fabricating from hundreds to millions of miniaturized electronic components such as diodes, capacitors, resistors, and transistors onto a semiconductor surface known as a wafer. This wafer is typically made of silicon.

Modern digital electronics can perform many functions, all while maintaining a relatively small size. For example, you cannot compare a 5-inch smartphone now with the first computer, which was at least 1,800 square feet large. The former used about 18,000 vacuum tubes besides other electrical components which it needed to function. The change in electrical device manufacturing took a considerable turn when transistors were invented. The transistors’ invention showed engineers that they could make electrical components that were small, easy to work with, sturdy, more reliable, and cheaper than vacuum tubes.

The invention of transistors challenged engineers and led to the design of other electrical components such as resistors and capacitors. In 1958, John Kilby invented the first integrated circuit, and six months later, Robert Noyce fabricated an interconnected IC to a single silicon chip. The production of IC chips in foundries involves the etching of the electronic circuit onto a semiconductor chip using the photolithography process. However, they are generally produced in mass, with many circuits being etched onto a single wafer.

The wafer is then taken to a packaging company for dicing and packaging. Dicing is the process of concisely cutting up the wafer to separate the wafer into individual chips or die containing a single circuit. A microchip can be anywhere from a few square millimeters to a few square centimeters. After the dicing is the actual packaging. Packaging involves encapsulating the chips into a supporting case to prevent corrosion and physical damage. The packaging is done so pins (electrical contacts) are left, which will be connected to a circuit board.

At this point, packages have to be tested. This testing, done using test sockets, is meant to allow the identification and eventual elimination of faulty ICs. There are many types of test sockets, for example, a high-frequency socket which tests packages that emit or receive high frequencies. The growth of the electronics industry has led to a growth in the testing industry. There are now some companies such as tts group that work directly with packaging industries to create highly specific and high-quality testing tools.

There are many advantages of using IC circuits. These advantages have led to high demand for ICs. They are used in automotive controls, portable devices, computers, televisions, and even microwaves. The military has found ways to incorporate them into their equipment, and they are also used in data processing and in switching telephone circuits.