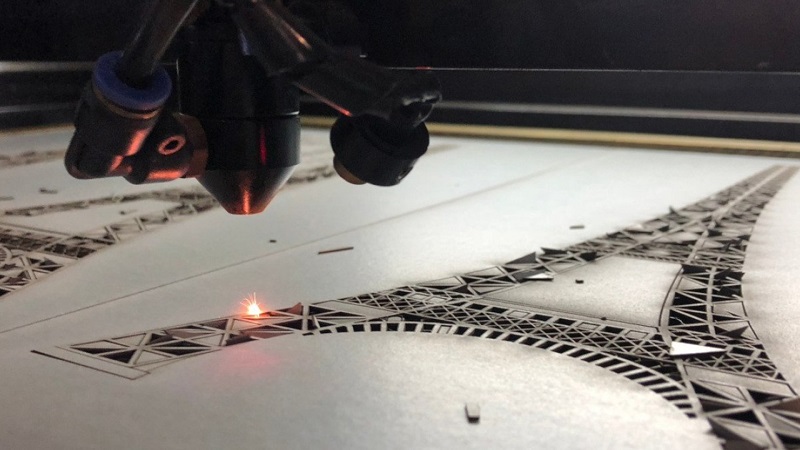

Engravings made with laser, are identified as being processes in which there is no direct contact between the machine executing the action and the surface on which it is being performed. What makes the bridge between both objects is precisely a laser beam that alters and erodes the material in which it is worked, so laser cutting machines not only fulfil this engraving function, but also completely cut the surface of according to the form that the operator wants to give it.

Features and uses of a laser cutting machine

One of the main characteristics of these machines is their different levels of engraving or cutting. These can range from millimetre to metric sizes and depends on the material, the reaction may be different. It should be noted that any product containing PVC should not be introduced into the machine since it releases chlorine gases on contact with lightning. In most cases, these machines are used to cut or engrave metal objects, in fact, the automotive industry bases its entire application on machines of this type, although much larger and more elaborate.

Basically laser cutting machines combine heat and pressure to achieve your goals. Most of this equipment is measured in Watts. The recommended power is from 30W – and the cutting intensity is proportional to the size and thickness of the material to be worked. If it is the first time that you are going to acquire a laser cutting machine, it is recommended that you focus more on the performance of the machine, that is, on the quality of the laser beam transmission optics, rather than its power or intensity. Here precision plays a very important role and it is very valuable to have this element as a priority.

How does a laser cutting machine work?

Before purchasing a laser cutting machine, it is recommended that you know how it works and what its main components are. Physically, the machine looks like a huge printer, which has a focused laser beam that can treat, melt or evaporate surfaces such as acrylic, rubber, wood, textiles, and paper, among others. The laser has a determined power that comes from the generator and a conduction system that through a nozzle directs the beam towards the work piece.

What space does a laser cutting machine take up?

Most of the machines laser cutting has a table that ranges from 30 cm to 90 cm x 50 cm x 140 cm. It is important that you take into consideration before purchasing the equipment, the space and the conditions where you will have them. However, it should be noted that the larger the cutting area, the greater the amount of work you can do in parallel.

Whether it is to start a business or to dedicate time to a new profession, it is very important in advance to have a security system that avoids the risk caused by laser radiation or the materials it cuts. Always have glasses that can protect you from such radiation, despite the fact that there are laser cutting machines with different levels of radiation.

Conclusion

If you have your own furniture company where you make stylish metallic furniture along with wooden material, then you should buy laser cutting machine from a reputed wholesaler. So go online and visit https://emitlaser.com/ this site for purchase. It allows cutting very fine geometries of any shape. In addition, with the integrated camera, you can recognize registration marks and automatically compensate the cutting path, even if the original template goes out of alignment, is rotated or distorted.